Citabria 9091L Restoration Part 3

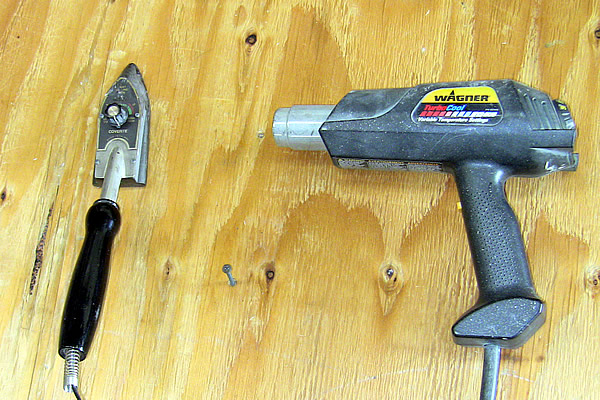

Mar 06 2011 · 0 comments · NewsDid you know that a hair dryer and an iron are essential tools for building an airplane? Yes indeed! The hairdryer is used to tighten the fabric once it is put on the frame, and the iron is used to iron out little wrinkles in tight places or round corners.

The method of covering has not changed much since the Wright brothers and John Montgomery. The material has changed from cotton or linen to synthetics that do not get mildew or get eaten by insects or mice, and instead of leaving the fabric “naked” it is covered with protective coats of dope. The fabric (trade name Ceconite) is 100% polyester, and woven so as to prevent any rips or tears propagating (ripstop). If you come to the hangar and ask to see it we’ll show it to you and have you try to tear it. It comes in large rolls about four feet wide and is cut and shaped and glued to the frame.

In the case of wings the fabric is also riveted to the ribs. Lift over the wing will lift off the fabric if it is not properly attached. Glue alone is not enough. Once the fabric is on and heat shrunk, protective tapes are added in stressful places and over joins, then the doping starts. Nitrate dope is brushed on by hand for the first coat or two. It penetrates the weave and sets up a good substrate for the later butyrate coats. It looks greenish when dry.

Once the nitrate is done, the work can be left to wait. However if the fabric is left to wait before any nitrate is applied, dust will get into the weave and make it very hard to achieve a good coat later. So it is essential to complete the nitrate dope covering as soon as the new fabric is put on the plane.